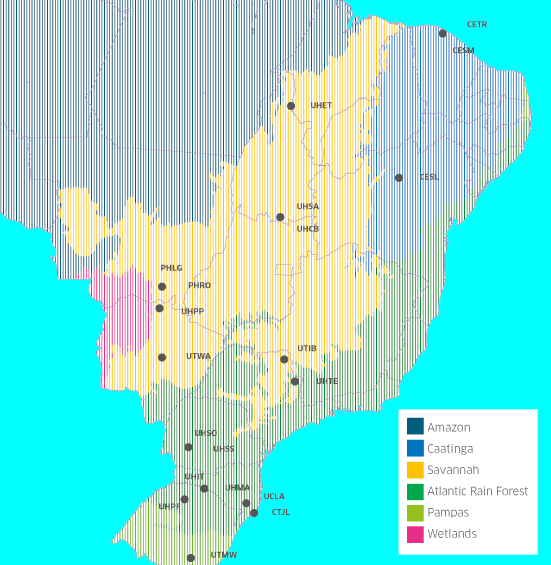

| Itá HPP |

| Location: Between the municipalities of Itá (SC) and Aratiba (RS). |

| Reservoir area: 142 km2. |

| Permanent Preservation Area (APP): 22.56 km2. |

| Regional biodiversity: 27 species of mammal, 94 species of birds, 31 species of reptiles, 11 species of amphibians, 40 species of fish and 60 species of flora (tree species). |

| Convervation Units: Parque Estadual Fritz Plaumann (SC), 7.41 km2; Parque Municipal Teixeira Soares (RS), 4.61 km2; Parque Municipal de Preservação Ambiental de Severiano de Almeida (RS), 0.15 km2. |

| Cana Brava HPP |

| Location: Cavalcante (GO). |

| Reservoir area: 139 km2. |

| Permanent Preservation Area (APP): 3.2 km2. |

| Regional biodiversity: 92 species of mammal, 304 species of birds, 98 species of fish, 41 species of amphibians and 77 species of reptiles. |

| Convervation Units: Avá-Canoeiro indigenous reserve. |

| Passo Fundo HPP |

| Location: Entre Rios do Sul (RS). |

| Reservoir area: 151 km2. |

| Permanent Preservation Area (APP): 4.11 km2. |

| Regional biodiversity: 18 species of mammal, 122 species of birds, 14 species of reptiles, 10 species of amphibians, 44 species of fish and 20 species of flora. |

| Convervation Units: Parque Estadual Rondinha, 10 km2; and Reserva Municipal da Sagrisa, 4 km2. |

| Machadinho HPP |

| Location: Between Piratuba (SC) and Maximiliano de Almeida (RS). |

| Reservoir area: 79 km2. |

| Permanent Preservation Area (APP): 44.05 km2. |

| Regional biodiversity: 52 species of mammal, 192 species of birds, 63 species of fish, at least 2 important species of reptiles and 522 species of flora. |

| Convervation Units: Parque Florestal Estadual Espigão Alto (RS), 13.33 km2. |

| Salto Santiago HPP |

| Location:Between Rio Bonito do Iguaçu and Saudade do Iguaçu (PR). |

| Reservoir area: 208 km2. |

| Permanent Preservation Area (APP): at the time the plant was built, mandatory acquisition of areas for the formation of an APP was not required by the legislation. |

| Regional biodiversity: 14 species of mammal, 302 species of birds, 14 species of amphibians and 39 species of fish. |

| Ponte de Pedra HPP |

| Location: Between Itiquira (MT) and Sonora (MS). |

| Reservoir area: 14.5 km2. |

| Permanent Preservation Area (APP): 7.8 km2. |

| Regional biodiversity: 80 species of mammal, 249 species of birds, 58 species of reptiles, 17 species of amphibians and 9 of invertebrates. |

| Convervation Units: The plant reservoir lies adjacent to the Parque Estadual da Serra de Sonora with an area of approximately 79 km2. |

| José Gelazio da Rocha SHP |

| Location: Rondonópolis (MT). |

| Reservoir area: 0.27 km2. |

| Permanent Preservation Area (APP): The legislation does not require the installation of an APP along the plant’s reservoir margin. |

| Regional biodiversity: 80 species of mammal, 249 species of birds, 58 species of reptiles, 17 species of amphibians and 9 invertebrates. |

| Convervation Units: Parque Estadual Dom Osório Stoffel, 64.22 km2. |

| Salto Osório HPP |

| Location: Between São Jorge d’Oeste and Quedas do Iguaçu (PR). |

| Reservoir area: 55 km2. |

| Permanent Preservation Area (APP): At the time the plant was built, mandatory acquisition of areas for the formation of an APP was not required by the legislation. |

| Regional biodiversity: 13 species of mammal, 303 species of birds, 9 species of amphibians and 39 species of fish. |

| Rondonópolis SHP |

| Location: Rondonópolis (MT). |

| Reservoir area: 0.024 km2. |

| Permanent Preservation Area (APP): Legislation of the day did not require the installation of an APP along the reservoir margins. |

| Regional biodiversity: 80 species of mammal, 249 species of birds, 58 species of reptiles, 17 species of amphibians and 9 invertebrates. |

| Convervation Units: Parque Estadual Dom Osório Stoffel, 64.22 km2. |

| São Salvador HPP |

| Location: Between São Salvador do Tocantins and Paranã (TO). |

| Reservoir area: 104 km2. |

| Permanent Preservation Area (APP): 47.53 km2. |

| Regional biodiversity: 26 species of mammal, 242 species of birds, 38 species of reptiles, 29 species of amphibians and 209 species of fish. |

| Convervation Units: Environmental Protection Area of Lago de São Salvador do Tocantins, Paranã and Palmeirópolis, 145.25 km2. |

| Estreito HPP |

| Location: Between Estreito (MA), Aguiarnópolis and Palmeiras do Tocantins (TO). |

| Reservoir area: 555.0 km². |

| Permanent Preservation Area (APP): 125.0 km². |

| Regional biodiversity: 2 species of aquatic mammal, 164 species of birds, 21 species of reptiles, 38 species of amphibians and 50 species of fish. |

| Convervation Units: The reservoir is adjacent to the Monumento Natural das Árvores Fossilizadas Conservation Unit, 356.3 km². |

| Areia Branca SHP |

| Location: Caratinga And Ipanema (MG). |

| Reservoir area: 1.36 km². |

| Permanent Preservation Area (APP): 112.71 hectares surrounding the plant reservoir. |

| Regional biodiversity: 17 species of mammal, 191 species of birds, 6 species of reptiles and 20 species of amphibians. |

| Convervation Units: No such units directly in the affected area. |

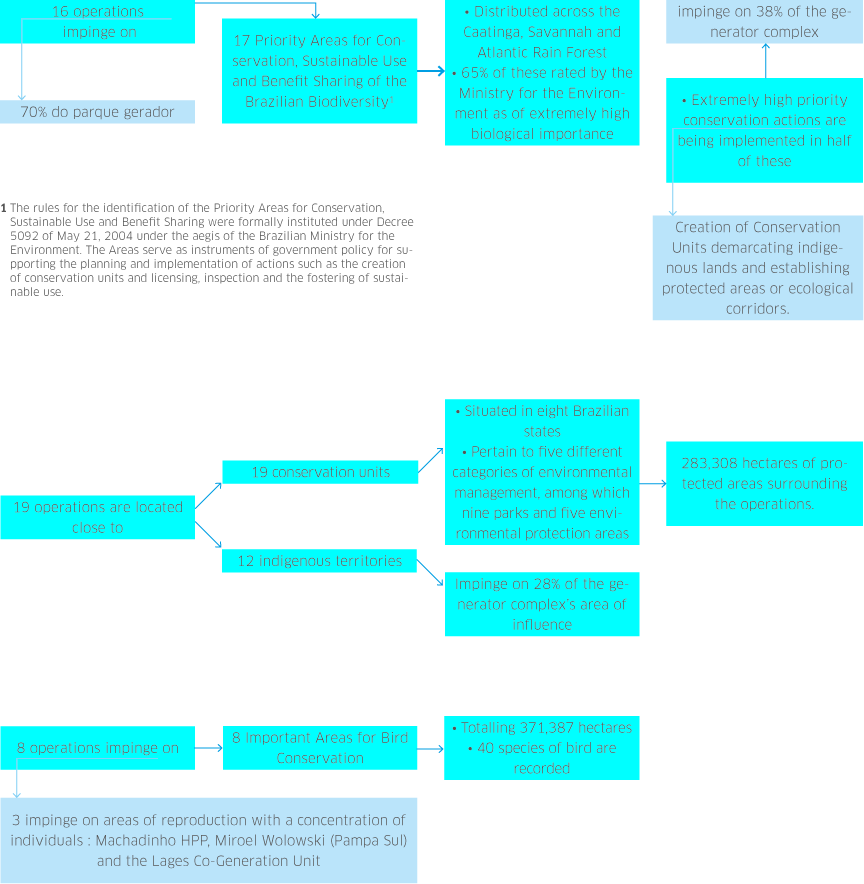

As a practice, ENGIE Brasil Energia compensates for the installation of its operations by supporting the creation and maintenance of Conservation Units in some regions where it carries on its business. Examples of this practice are Parque Estadual Fritz Plaumann in Concórdia (SC) and Parque Natural Municipal Mata do Rio Uruguai Teixeira Soares in Marcelino Ramos (RS), both located in the Itá Hydroelectric Plant’s sphere of influence.

Yet another practice which collaborates with the conservation of biodiversity, is the Program for Planting and Donating of Seedlings. Among the program’s activities are the cultivation and distribution to communities of flora, native to the region in which plant operations are located. In 2016 alone, the Company planted and donated 340,269 seedlings.