The Integrated Management System (SIG) together with corporate policies provide the underlying guidance for the management of the Company’s manufactured capital and covers five dimensions: quality, environment, occupational health and safety, social responsibility and energy management. In all, 14 of the 29 plants which ENGIE Brasil Energia operates are certified according to NBR ISO 9001 (quality), NBR ISO 14001 (environment) and NBR OHSAS 18001 (Occupational Health and Safety) standards. In 2016, Estreito HPP was certified under these standards, thus increasing the percentage of certified installed capacity from 83.6% to 95.3% – this discounting the non-renewal of Charqueadas TPP’s certification in the light of the closure of plant activities.

The Jorge Lacerda Thermoelectric Complex, which has three plants among the 14 certified, has also certification according to the NBR ISO 50001 standard with respect to Energy Efficiency. The Company seeks to adhere to guidance under the NBR ISO 26000 standard (for which there is no certification) on social responsibility.

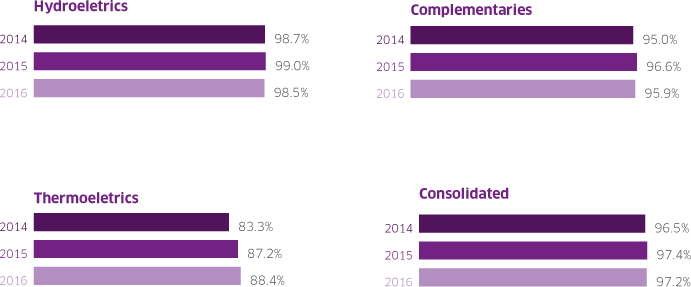

The percentage of certified installed capacity of the Company reached 95.3% in 2016.