Transportation of wood to the plants is mainly done by highways, due to the logistics model of the country. We also adopted the use of barges between the Caravelas Terminal, in Bahia state, and Portocel, Espírito Santo state, a more sustainable means of transportation since it emits less carbon dioxide and contributes to reducing truck traffic and, consequently, risks of road accident. In partnership areas, from Minas Gerais to Aracruz, Espírito Santo state, we use rail transportation. The mill in Espírito Santo also receives wood transported by ship between the port of Rio Grande, Rio Grande do Sul, and Portocel, Espírito Santo, - in an operation that has provided much knowledge and opportunity for Fibria's wood logistics in the last two years.

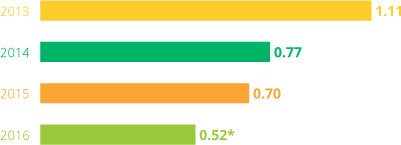

Accidents per million kilometers traveled

* Reduction of 29% compared to 2015.

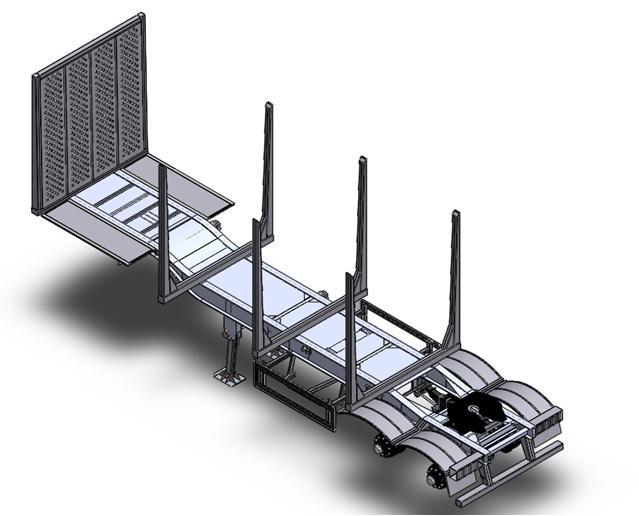

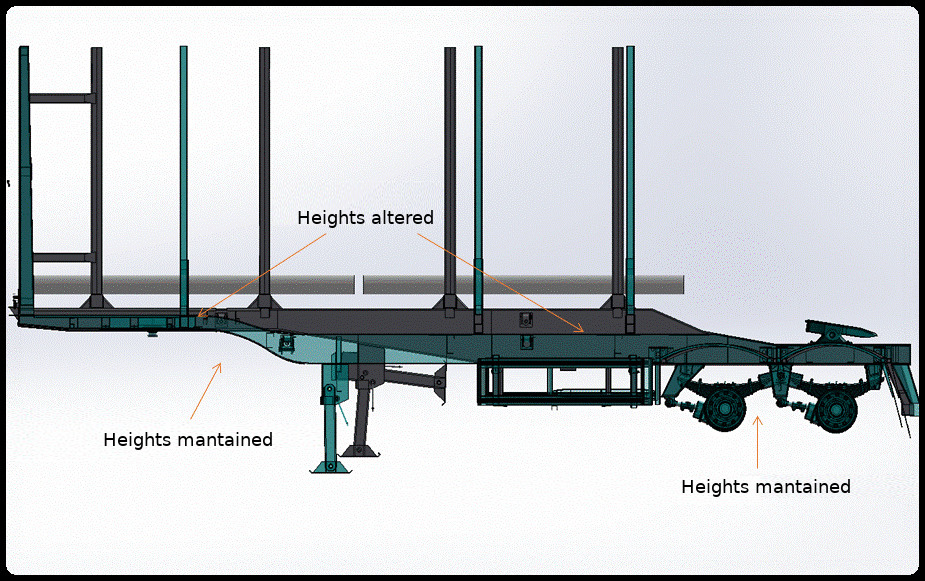

In 2016, we implemented the PIFFs (Fibria Forest Implementation Project), trucks with lighter body-frames, with capacity to transport 10% more wood from the forests to our mills. The project provides important economic, and social and environmental benefits. In addition to reducing the impact caused by traffic in the communities close to Fibria (since it reduces the number of trucks necessary for operations), it also generates savings of 3,862,094 liters of diesel and avoids emission of 9,514 tCO2e. The PIFF was developed in partnership with the Federal University of São Carlos (UFSCAR) and patented by Fibria.

Protection of Whales

Since 2003, Fibria has been transporting wood in ocean-faring barges, from its forestry base in Southern Bahia, leaving the Caravelas Terminal, BA, to the Portocel Terminal, ES, from where the cargo is taken to supply the Aracruz, ES, unit. As a result, nearly 100 tritrem trucks (hauling three trailers) per day are taken off the roads in the region, thereby reducing social and environmental impacts.

While preparing the feasibility studies for this operation, the company identified that this section of the sea is visited in winter by humpback whales, which come to reproduce in the southern portion of the coastline in Bahia. The solution was to establish two routes for our barges - in summer, more distant from the coastline, and in winter, closer to the coastline in order to avoid harming the reproductive cycle of whales. This procedure has been in place for 16 years.

Challenge Overcome

Open and structured dialogue enabled us to overcome challenges in the complex process to transport wood through coastal shipping, addressing two of our business commitments: on the one hand, using wood contracted in Capão do Leão, Rio Grande do Sul state, and, on the other, supplying the Aracruz mill, which needs additional raw material to compose its pulp production.

Decisions focused on financial management led the company to reduce investments in its forest base in Aracruz, Espírito Santo, opting for minimum management of operations, which resulted in lower productivity. Over the past two years, we have felt the effects of the low availability of wood in our operation and, consequently, we had to quickly find a solution to supply our mill.

The alternative was to source wood from Capão do Leão, which was part of a stock purchased in partnership contracts entered into by the company in that same year. Transportation through coastal shipping has proved to be the best option, since ships have higher cargo capacity and generate less environmental impact. However, it has the downside of increasing company costs.

In 2015, the company planned, organized, and started the operation. By 2016, however, conflicts between the communities of dockworkers at both ends of the business became a liability. We realized that it was necessary to adjust models for wood loading and unloading - and we began a series of conversations to identify bottlenecks and what we would do to correct them.

In Espírito Santo, engagement was instantaneous, which allowed a group of dockworkers, union leaders, and employees of Portocel, Espírito Santo, and Fibria to go to Capão do Leão, to establish a form of operation satisfactory to all. At the end of 2016, came the celebration: we successfully transported 1 million m³ of wood, in other words, we loaded 45 vessels as of July 2015, and maintained stable pulp production in Aracruz. The operation will extend until it reaches 3 million m³ of wood transported, which is expected to occur in the first half of 2019.

To supply the production of Aracruz, we are also increasing the transportation of wood by rail between Minas Gerais and Espírito Santo. There will be nearly 500,000 m³ or a little over 300 railcars, with clear social and environmental gains. The use of highways would mean more truck traffic, pollution, and exposure to accidents.

Photo: Fibria archive.

INVESTMENT IN INFRASTRUCTURE EC-7

| 2014 | 2015 | 2016 | |

|---|---|---|---|

| Aracruz* | 353,774 | 220,781 | 551,441 |

| Jacareí** | 1,622,632 | 2,737,552 | 3,043,305 |

| Três Lagoas*** | 1,357,936 | 4,011,421 | 5,953,508 |

| Total | 3,334,342 | 6,969,754 | 9,548,254 |

* - CBC intervention in the opening of Boca da Barra

- Dredging of the Boca da Barra Canal - WA Serviços Marítimos

- Community requests (SISPART

- Does not include maintenance/improvements to roads associated with forestry operations

** Includes Capão Bonito and Vale do Paraíba.

Amounts extracted from SISPART and the area of logistics/roads, considering amounts that benefited the community.

Humidification.

*** Reports with evidence on forestry logistics and pulp logistics.