One of Fibria's Long-Term Goals is to reduce by 91% the solid waste disposed of in our industrial or in third-party landfills by 2025. In order to achieve this goal, a set of initiatives has been designed and implemented every year, always focusing on integrated waste management and the application of our 4Rs concept - reinvent, reduce, recycle, and reuse.

Lime sludge and boiler ash are some of the solid waste generated in the production of pulp. At Fibria, this material has been used for the production of a soil acidity corrective since 2013. In 2016, the three mills combined produced 87,000 tons of corrective, which generated savings of approximately BRL 11 million in the purchase of limestone for the company's eucalyptus forests.

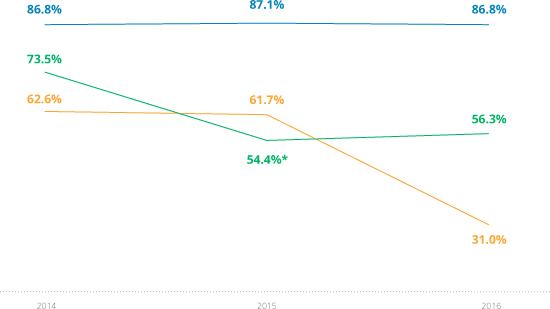

REUSED INDUSTRIAL SOLID WASTE

* Reuse of industrial solid waste at the Jacareí plant in 2015 was impacted by the increase in the production of biological sludge.

The most recent project focused on reducing solid waste is the use of equipment for drying biological sludge, a kind of waste generated in the treatment of effluents and that is also usually taken to landfills. When dry, 90% of the sludge can be burned in boilers, generating energy. With an investment of around BRL 18 million, this system is being implemented at the Jacareí mill. We estimate that the mill will stop sending to landfills 35,000 tons of sludge per year. In the Três Lagoas, Mato Grosso do Sul, unit, which has a drying process similar to that of Três Lagoas, 86% of the biological sludge generated is reused as fuel in the auxiliary boiler.

Currently, we reuse 91% of industrial waste, including ash, lime sludge, primary sludge and scraps from the process, among others. Part of this volume is not suitable for internal use, but can be donated or marketed as raw material for industries in various sectors. In 2016, we sold 886,000 tons of industrial waste, amounting to BRL 4.2 million, and avoided the cost of BRL 31.8 million that we would have had if we sent it to landfills.

Read the artigo Valorização Econômica e Ambiental de Resíduos.

in recovery area in Três Lagoas (Mato Grosso do Sul).

Photo Márcio Schimming.